EWPs or elevating work platforms are used in so many different industries and this allows workers to access these areas ensuring their safety. These can be used for installation tasks, construction and maintenance. But you need to make sure that the elevating work platforms are safely positioned and operated so that the wellbeing of workers is maintained.

There are various equipment types

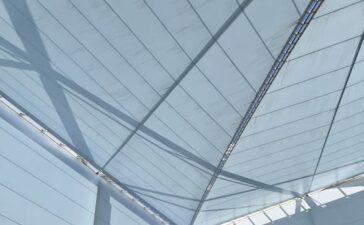

That are considered under elevating work platforms such as book lifts, scissor lifts and cherry pickets. These will elevate equipment as well as workers to certain areas. There is a basket or platform that is mouthed on an articulating or telescopic arm. This will be supported by a mechanical or hydraulic lifting mechanism. If you are planning to work in elevated spaces, you can look into EWP training. Here, you will learn how balance, stability and safety can be ensured by the proper positioning of elevating work platforms. Before the elevating work platform is deployed, a thorough assessment of the site has to be carried out so that you can identify any obstructions, potential hazards or terrain conditions that will affect how you position the platform. You have to consider the stability of the ground, proximity of the equipment to power lines and overhead obstructions in this situation. Also consider the presence of equipment and workers in the area and how this will increase risk.

The elevating work platforms

Has to be positioned on level ground so that it is stable and doesn’t have a risk of tipping over. The platform can be stabilized using outriggers or levelling jacks if you are working on an uneven terrain. This will give you assurance that the wheels or tracks are planted firmly on the ground. There should be sufficient clearance around the elevating work platform so that the risk of colliding with other equipment, obstacles and structures is reduced. You need to make sure there are no obstructions overhead such as tree branches, power lines or building facades that can impede the movement of the platform. You need to make sure that the elevating work platform is positioned a safe distance away from hazardous areas, edges or drop-offs so that it doesn’t tip over. Another risk you face here will be workers falling when they are working at the edges. To prevent this, there should be toe boards, guardrails and safety harnesses.

The stabilization system

Of the platform has to be engaged whether these are stabilizer legs, outriggers etc. so that it cannot tip over during operation. There are manufacturer’s guidelines you can follow in order to ensure safe operation. There should be clear communication protocols in the workplace between personnel on the ground and the operator of the elevating work platform. This ensures that the platform is positioned correctly. You can use communication devices such as radios or use hand signals. You need to follow the proper procedures that are defined for positioning and stabilizing the elevated working platform so that the workers’ wellbeing can be ensured. This is critical when it comes to minimising risks and preventing injuries and accidents.